Hilux Project Part 3

In Part 1 of this build series we took a deep dive into the initial build phase, Part 2 followed on from this and covered the build right up to the moment where it was ready to run. Here in Part 3 we get it fired up and start the testing phase to see if 3 years of hard work is worth it.

The long nights continued in readyness for the guys from STM in New Zealand to come over and wire the car, the plan was that they would stay at my place for 5 days till it was complete, in just 3 days the chassis and engine was wired and we were ready for tuning.

With thanks to DTM in Geelong I was able to have access to a dyno for the day, with all fluids checked and the base tune sorted we could begin to start mapping the engine.

You want the numbers? Well how does 336rwkw and 855kg sound? Yep I was happy with that, pump fuel, tiny little turbo pumping 22psi and a healthy torque curve how could you not be happy?

With the tune complete I could now ready all systems for driving. The removable front clip that I toiled for so long on was coming into its own, the drybreak oil cooler and Pegasus (cheap wiggins) clamps made life a breeze.

I am always thankful for supportive parents, they purchased this enclosed ex sprintcar trailer and organised my hometown go kart track for initial testing, I am truly lucky to have so much family support.

The first time I rolled this out on track I was a little taken back, I had never really had the room to step back and see this build in its entirity, had I made the right choice on the wheelbase? Had I got the proportions right, are the wheels in their right positions? All of the questions were answered on this day.

It might of handled like a go kart but the 336rwkw was a little overkill. What I was suprised with was the drive from the rear axle, this really gripped up once the tyres were warm and when it it broke traction it was violent, twitchy, with very little flex in the whole car. I think the swaybars are overkill and might not need to be on there at all but I wouldnt say any of this was a bad trait, I just needed to go faster on a bigger track.

Back home and the bodywork continued, the guys from IPTA in Geelong were amazing, they made the molds and produced the panels.

Remember in Part 2 where I spoke about the tabs and how I handcut them all? Here is a 5 image explainer about how that goes.

With all the tabs made this was the first time that the Hilux had all its bodywork on, I still needed to cut the guards but I was so excited about how good it looked.

My good friend Matt Cox was filming a short documentary on this build, we took this moment in the middle of winter to do some on road testing and filming.

I’ll forever be grateful to Matt for telling my story through this medium, I never worked in the dark but it made for a moody setting.

I sprayed lanolin oil on this chassis daily for three years to allow myself the opportunity to clear coat the steel, I am a massive advocate for raw colours and steel has such an organic finish that I wanted to keep. I ran a test with my BMX frame that I stripped, scotchbright’d (always running round the tube not along it) and powdercoated clear. It looked amazing and held up well in the few weeks I tested it for.

In 4 hours everything was coated and baked and then ready to take home, I filled every thread with a sacrificial bolt to maintain the threads clenliness and the moment I got home the sunset lit the bare steel and I was in love. The depth and the golden gloss was everything I had hoped for.

My friend Tim from Breakwater Panels sprayed the bodywork for me and I reasembled all the components, The white against the steel was perfection.

The assembly of all sub systems had begun.

The manifold was ceramic coated, I welded the exhaust housing to the manifold and the V band dump pipe adapter onto the turbo housing, this made for a strong join without the need for gaskets.

You already know I am little crazy right? Well my good friend Dean Walters is also crazy, he agreed to do a special photo shoot where we timelapse individual rooftop shots into a full exploded build up. I loaded up all the parts and we set it up.

While Dean mounted the camera to the rafters I set up the layout.

I made a roll in engine stand, I accounted for every nut and bolt, I had everything ready to go.

From this to this in around 8 hours.

Watch it all come together.

Back together and back home, I had a present waiting for from Helmart Designs in New Zealand, just in time for a test run.

The first proper run was at Winton Raceway and it was nervous, excitement and a little anxiety all rolled into one test session. I loved the handling, it was predictable at speed which I loved but I just felt like there wasn’t enough power and I couldn’t understand it.

With the help of my family we dragged the Hilux and my 180SX up to demo and compete in WTAC. The reception was incredible, I lost my voice on day one from speaking to people who followed this build, I was overwhelmed. How was the first proper drift session? Not great….. I actually broke third gear in the gearbos and subsequently overreved the engine and broke a rocker. I got 5 good laps but the car still felt underpowered.

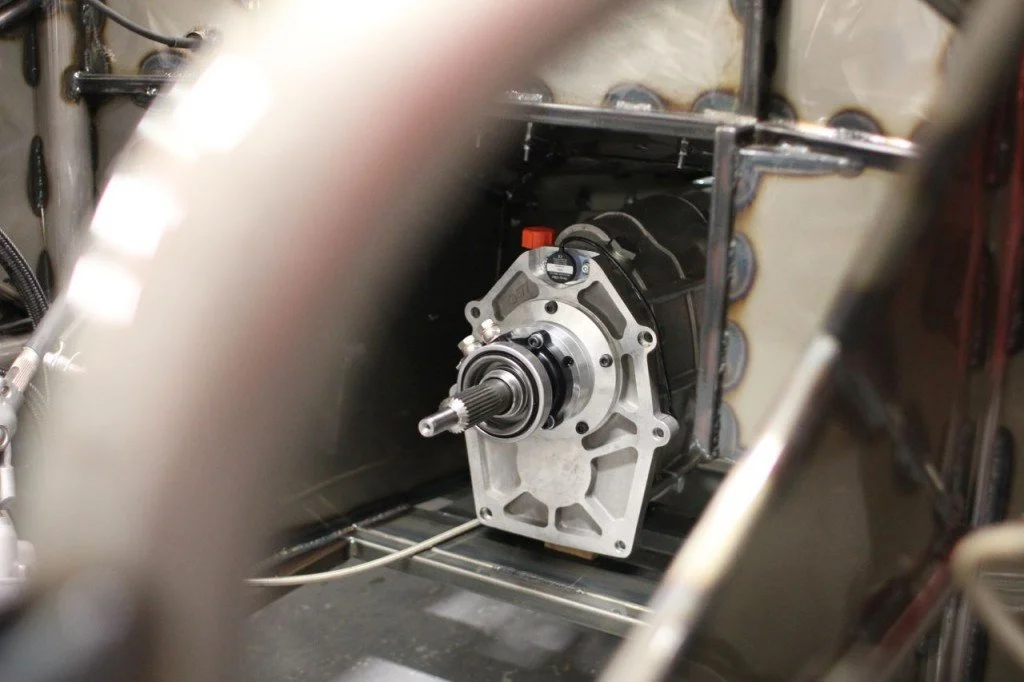

This where things got expensive, I was set to internationally debut the Hilux in New Zealand and I had two weeks to fix the gearbox, frightened that another RB25 gearbox wouldnt be up to the task I found a guy selling a QBE69G Quaife 6 Speed Sequentially shifted gearbox. I sold whatever I could and bought it for $14,000 along with some appropriately splined clutch disks and throwout assembly.

I had one week to make all this work, I designed and machined an adapter for the Auto Bellhousing and then finalised all the mounts, throwout setup, tailshaft and reassembled the whole deal.

With a day to spare it was all together again.

I had 2 hours to test it before putting it in the trailer to ship out. It still felt underpowered and I was a little nervouse. But the gearbox was incredible, the extra gear, the tighter ratios, the instant shifts I was in love….. Oh and the sound!

I had a rare break while the Hilux was on the water to New Zealand, it gave me a chance to reflect about how wild life had become and how this build had positively affected my lifestyle.

New Zealand was a whole new ball game, the support was insane, I held a night where I completely dissasembled the Hilux down to its chassis and built it up right there on the floor with a VIP group who watched on and asked questions. I was mic’ed up the whole time and explained every detail as it went back together.

Matt flew over to finalise his documentary Dream Build Drive, to do this we hired the Hampton Downs racetrack and a crew of profesionals that would be directed by Matt. It was a wild experience, the Hilux still felt underpowered and towards the end of the day broke an axle. But we had enough shots to finish the documentary and Matt got to work editing.

Again I will be forever thankful to Matt for capturing this amazing time in our lives.

I sourced an R33 GTR diff and shafts to solve the broken axle situation and then finally had a chance to see what power it was making. Turns out that when I had removed the engine after intial tuning for powdercoating the timing has synced 180 degrees out, it produced 170kw on the dyno and then after finding the fault we turned it back 180degrees and it made 340rwkw. I wasn’t crazy and I was about to get the biggest shock of my life with that power curve. Think about that for a moment, Dream Build Drive was filmed with 170rwkw, I cant imagine what the driving could have been like with double that.

My final stop on the New Zealand tour was Manfield Raceway, thousands of people came to see the Hilux perform and having never driven it with this power it was a whole new experience. I drove out of the show hall after the unveil and then out to the track, I had a sea of people following and I was a nervous wreck. I learnt fast and got the hang of it.

Back home and the good times kept rolling.

I drove to Queensland for the Matsuri at Queensland Raceway.

The Hilux was flawless and I loved flowing around this circuit.

Then to WTAC in Sydney for the 4th time. This time running the whole track with the worlds best drivers.

The next few months involved some maintenance and then plenty more driving at events all across the country.

I especially like this video, this is how I want to display this build, clean, in control, flat and fast. I have had a few moments where it all clicks and it’s an incredible feeling, it sounds cheesy but I feel connected with the chassis, I can feel everything I built around me doing it’s job and I mechanically understand the car, that’s what I chase, it took a lot of work to get there but it has all been worth it.

Thanks for reading this Part 3 account of the ETS Hilux Build.